March 20, 2025

Neiafu Bay Vava’u, Kingdom of Tonga, 18 39.973 S / 173 58.919W

Perhaps it is time for an update? We are still in the Kingdom of Tonga, Vava’u to be precise. In the last post we talked about how we came to our decision to stay here for cyclone season. So far, this has turned out to be a good decision. The weather has not been perfect, knock on wood, we have not had even a near miss with a cyclone. There has been one north and a few east, which is fine by me. We have had our fair share of rain. When I mean rain, well…they measure that in inches per hour around here. It is incredible to see. But on the bright side it keeps the water tanks full and the temperature down. All this time has left with time for projects.

It’s a new car!!

Boats require a ton of maintenance and yes money to keep going. We recently took delivery of our new car (dinghy). The old one was simply not big enough for our needs and it was trashed. So we ordered a new one for True Kit in New Zealand and shipped it by boat. She might be a little to big for our needs, but I like her so far. Time will tell if we made the right choice. No time to dwell on that we have plenty to do.

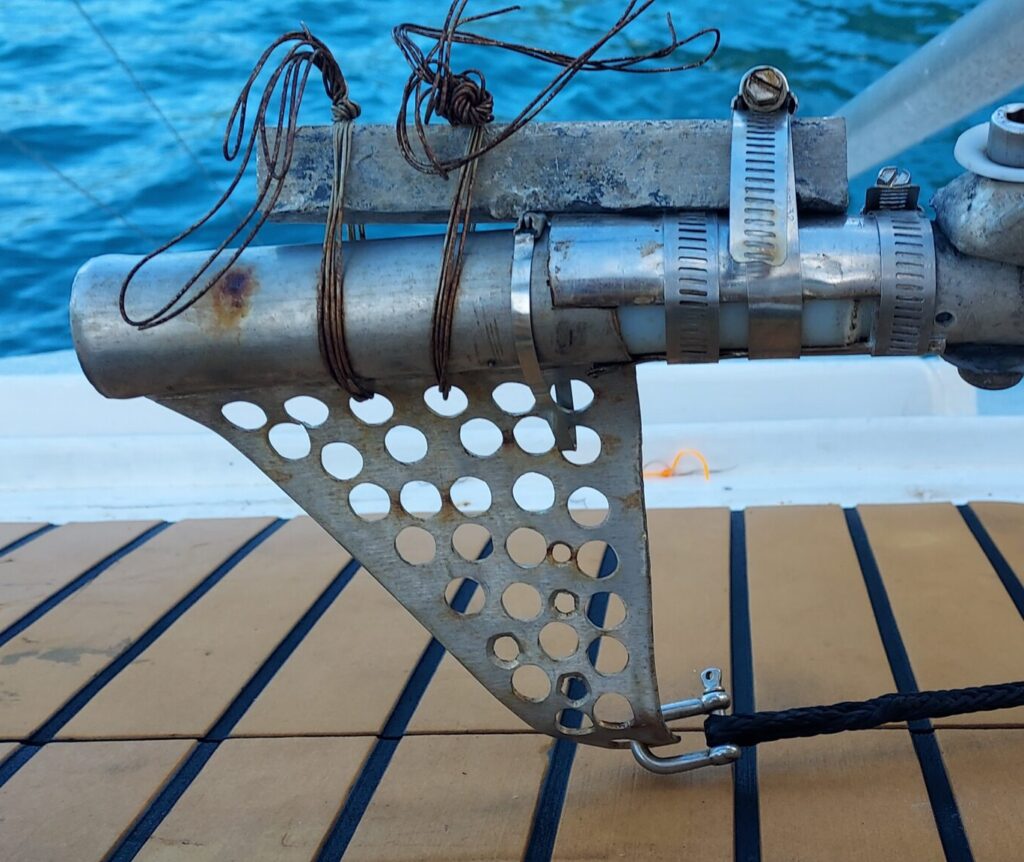

Fighting the Rust

Last season our trusty dive compressor started showing some typical salt air wear and tear. Last time Tami was I the US she brought back a rebuild kit for the Honda motor that powers the compressor. So I recently started that rebuild. She was full of rust and corrosion. After a lot of cleaning, scraping and painting she is back in her glory, although I have not started it yet. I was finally able to find the special oil the compressor takes (the oil has to be suitable for human breathing). You guessed it, that came from New Zealand as well. Starting to see a pattern here? But in the end it will be worth it as we can get back to diving on our terms.

Making Tartaruga work for us

Top load box refrigeration has been a problem for us. It means every time you cook, everything has to come out because for some reason what you need int eh frig is always at the bottom. Starting to believe in the Gnoems our Mexican friends believe in, another story for another time. So, like most men when Tami leaves, I feel compelled to tear something apart. So I removed the box refrigerator and replaced it with two small commercial refrigerators. I think the space inside is the same, but some are much easier to organize. Over time, it has become clear that having two of them is not really necessary, so I will sell one to a local resort and save some deck space. Additionally, the next thing is I will recess the entire unit into some worthless storage space. This will open an area where we can build new storage that makes more sense.

There has been a going toilet saga here on Tartaruga. As you may remember our boat was built in France, then sold to an Italian guy who eventually sailed her to Tahiti. So the toilet is fancy, electric with all the bells and whistles but I can not get parts for it. To set the stage, we have only one head, so if it is down this means a bucket or dinghy into land and use a toilet there. So after our boat yard time it stopped working, seized bearing. So I order a new one, one that I could source parts all over the world. This order was placed, air freight, October 31, 2024. To make a very long story short I recently received that toilet, 4 months later. A lesson on who not to do business with. But the bigger issue for Tami and me is that we do not like to discharge our waste into the local waters. So, we found a product called Electro Scan. This is a treatment system that treats our yucky smelly stuff such that when it is discharged it is 99.999% free of any pathogens or things that can hurt the environment or people. So soon a new pooper and cleaner, more on that later.

More exciting toys

There are many other things we have been working on. We took delivery of a new sail from Rolly Task. This is called a Cruising Code C, pictures to follow. Painting is an going challenge, not the work but the getting the paint. So, we will order that from New Zealand. There has been some engine repairs, left over issues from the lighten strike we think. Lots of little things. But it is not all work.

We have met some great people here in Tonga, after all they call it the friendly islands. Some are “palangis” (white people) that have relocated here and of course the locals. Most have been really great, you always have curmudgeons and we stay away from them. It is law in Tonga that no one is to make business transactions on Sunday, a decree of the King. This makes a great day for BBQ’s and hanging out with friends. It is nice to feel like part of a community. Until next time…